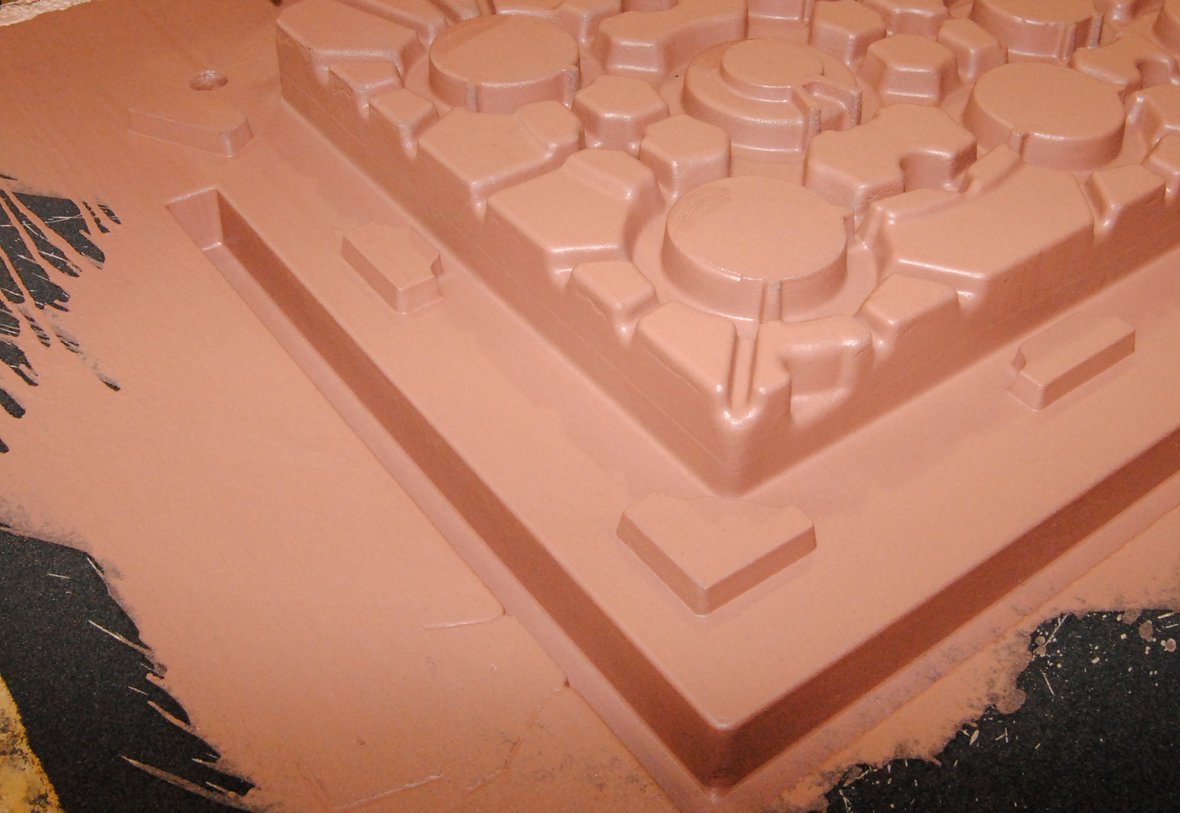

Introduction to refractory coatings

Foundry, mould or refractory coatings (sometimes referred to as ‘mould wash’) are a mixture of very fine refractory (high temperature resistant) minerals and / or coke and special additives in suspension with a liquid carrier and show the characteristics specified as follows

- Enhancing casting strip

- Enhancing metallurgical properties

- Increasing the temperature stability of the mould material

- Preventing metal-mould reactions (penetration, veining, erosion etc.)

- Optimising surface finish

In summary, mould coatings generate vendible castings without or just with little rework.

Common liquid carriers are fresh drinking water or organic solvents (e.g. isopropyl alcohol “IPA”). Coatings can be supplied in ready mixed form as a stabilized suspension that needs to be adjusted to its application state with usually small amounts of carrier liquid, whereas coatings supplied in powder form need to be mixed up properly at the customer. The success of this mixing procedure is very sensitive in respect of the used equipment, the different mixing times for each phase and, last but not least, the mixing operator. Hence, most foundries prefer a ready mixed supply where the supplier guarantees that the different additives are already activated and the coating is ready to be used. Additionally, not all additives can be supplied in powder form, restricting the application of such powder coatings.

Coating composition

Apart from the carrier liquid, the main components of mould coatings can be grouped as follows:

- Refractory fillers (inert and stabile towards formation of intermediate compounds)

- Binding agents (ensure wear resistance at room temperature)

- Ceramic agents (sustain suspension and ensure wear resistance during casting)

- Additives (control colour, foaming, preservation, penetration etc.)

Refractory fillers

Minerals are inorganic compounds that form and grow in dependence of the surrounding pressure and temperature. Some refractory minerals can be readily mined from the earth’s crust (e.g. Zircon) where others need additional treatments, usually calcination (Tabular alumina). Minerals are usually grouped by their chemical composition and atomic coordination. The crystal structure of minerals describes an ordered atomic arrangement, defining most of their beneficial but anisotropic (directionally dependent) physical and chemical properties.

Key characteristics of common refractories used in mould coatings

| Refractory | Key characteristic |

|---|---|

| Phyllosilicates | Minerals that actively counteract veining |

| Olivine | Best choice for simple castings |

| Mullite | Good refractoriness and application range |

| Alumina | High refractoriness, best application performance by flow coating |

| Magnesia | High refractoriness and inert with alkaline alloys or mould materials (e.g. Cr, Mn) |

| Zircon | Superior refractoriness and application performance |

| Carbon | High separation effect |