Chemical composition (typical values)

| Recarburising Material | Carbon content | Sulphur | Nitrogen | Ash content | Volatile content | Moisture |

|---|---|---|---|---|---|---|

| Low sulphur content LS | ||||||

| High purity, synthetic graphite | 99,00% | 0,015% | 0,003% | 0,10% | 0,10% | 0,01% |

| Synthetic graphite | 99,00% | 0,040% | 0,010% | 0,50% | 0,20% | 0,30% |

| Low sulphur petroleum coke | 99,55% | 0,100% | 0,07% | 0,05% | 0,20% | 0,20% |

| Graphitised petroleum coke | 98,90% | 0,070% | 0,040% | 0,50% | 0,40% | 0,20% |

| Natural graphite | 87,30% | 0,100% | 0,020% | 11,00% | 1,00% | 0,70% |

| Acetylene coke pellets a. granule | 99,25% | 0,030% | 0,030% | 0,10% | 0,40% | 0,25% |

| Low sulphur pellets | 98,10% | 0,080% | 0,050% | 0,50% | 1,30% | 0,10% |

| Medium sulphur content MS | ||||||

| Electrically calcined anthracite | 95,57% | 0,250% | 0,400% | 4,00% | 0,23% | 0,20% |

| Carbon pellets | 98,80% | 0,700% | 0,500% | 0,10% | 1,00% | 0,10% |

| Higher sulphur content HS | ||||||

| High sulphur petroleum coke | 99,30% | 1,200% | 1,000% | 0,20% | 0,30% | 0,20% |

| High nitrogen petroleum coke | 98,90% | 1,100% | 1,750% | 0,40% | 0,50% | 0,20% |

| Metallurgical coke | ||||||

| Metallurgical coke | 85,20% | 1,000% | 1,500% | 13,00% | 1,50% | 0,30% |

Solubility of carbon

The solubility of carbon depends on the interaction of the saturation level, the temperature and the time. Furthermore the agitation of the furnace, the slag content of the melt, sulphur content of the iron alloy and of the recarburiser as well as the carbon structure influence the solubility.

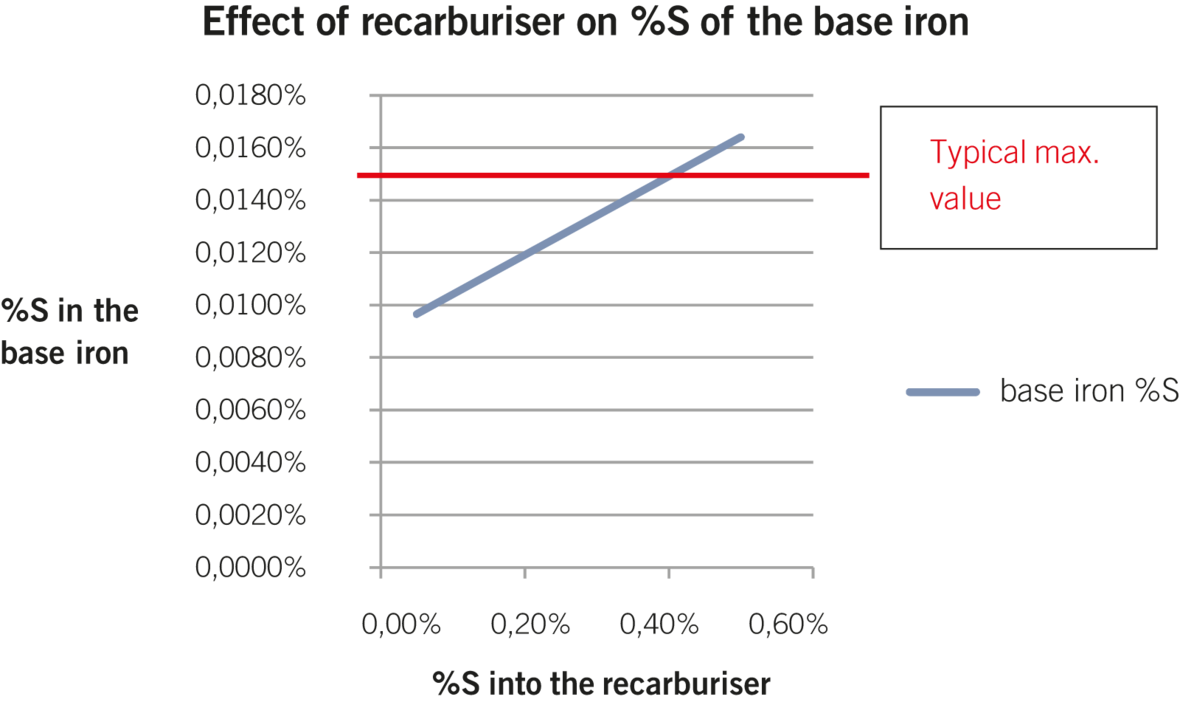

Sulphur content of the recarburiser

With recarburisers special attention to the sulphur content is important. The basic rule is, the lower the sulphur content, the higher the raw material costs. It is often observed that excessively low sulphur levels are targeted in iron and steel melts, which does not provide a tangible added value for the production of the relevant alloy.

Under ideal circumstances and besides the solubility, also the sulphur content of the recarburiser should be adjusted according to the application.

The diagram and the sample chart below show the sulphurisation of the base iron through the recarburiser with <0,05% S, 0,15% S up to <0,5% S. It becomes clear that a recarburiser like Procarb LS with <0,15% S – i.e. a product in the middle price segment – offers a better value for money than the carburisation with i.e. Premco SG, 0,05% S, a product with higher raw material costs.

| Content in kg | Content % | S-Cont. % of charge | kg-S of charge | |

|---|---|---|---|---|

| GJS composition with recarburiser <0,05%S – i.e. Premco SG | ||||

| Scrap steel | 5000 | 50,00% | 0,010% | 0,50 |

| Returns | 3500 | 35,00% | 0,008% | 0,28 |

| Pig iron | 1100 | 11,00% | 0,010% | 0,11 |

| FeSi and other alloys | 250 | 2,50% | 0,000% | 0,00 |

| Recarburiser | 150 | 1,50% | 0,050% | 0,08 |

| Sum | 10000 | 100% | 0,0097% | 0,97 |

| GJS composition with recarburiser <0,15%S – i.e. Procarb LS | ||||

| Scrap steel | 5000 | 50,00% | 0,010% | 0,50 |

| Returns | 3500 | 35,00% | 0,008% | 0,28 |

| Pig iron | 1100 | 11,00% | 0,010% | 0,11 |

| FeSi and other alloys | 250 | 2,50% | 0,000% | 0,00 |

| Recarburiser | 150 | 1,50% | 0,150% | 0,23 |

| Sum | 10000 | 100% | 0,0112% | 1,12 |

| GJS composition with recarburiser <0,5%S – i.e. Procarb 99 | ||||

| Scrap steel | 5000 | 50,00% | 0,010% | 0,50 |

| Returns | 3500 | 35,00% | 0,008% | 0,28 |

| Pig iron | 1100 | 11,00% | 0,010% | 0,11 |

| FeSi and other alloys | 250 | 2,50% | 0,000% | 0,00 |

| Recarburiser | 150 | 1,50% | 0,500% | 0,75 |

| Sum | 10000 | 100% | 0,0164% | 1,64 |